Tools Needed:

- Minwax Clear Aerosol Lacquer

- Minwax Polyshades Aerosol

- Aerosol adhesive

- Birch plywood backing

- Pine molding

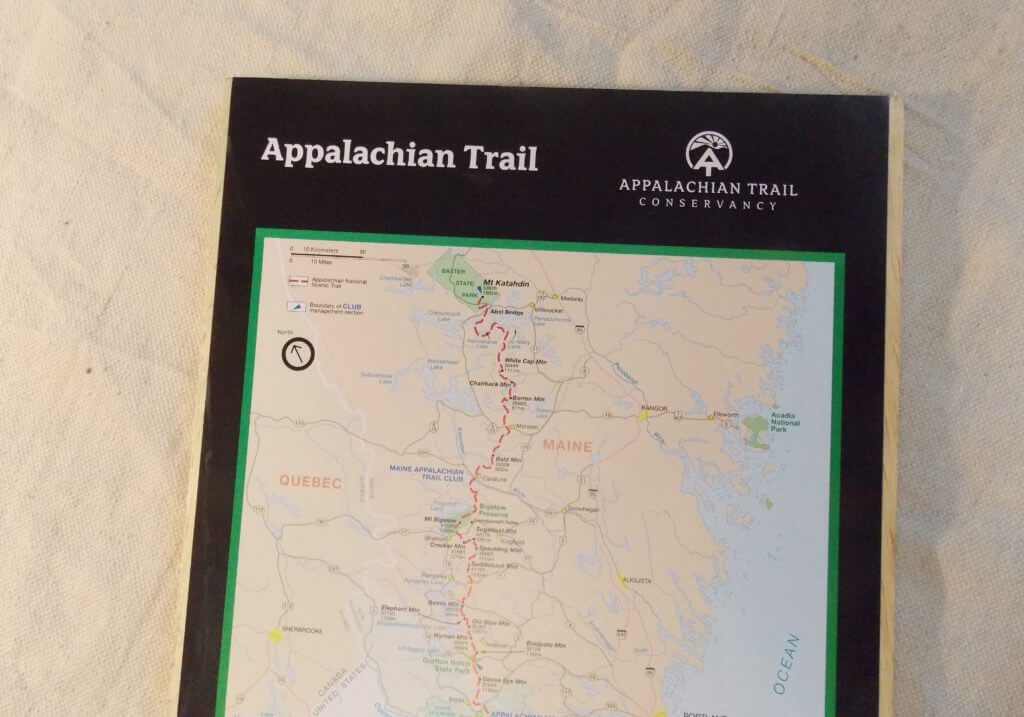

My son Eric likes to hike, so when I spotted this map of the Appalachian Trail, I knew he would love to have it hanging in his apartment.